- HOME

- Product

Product Details

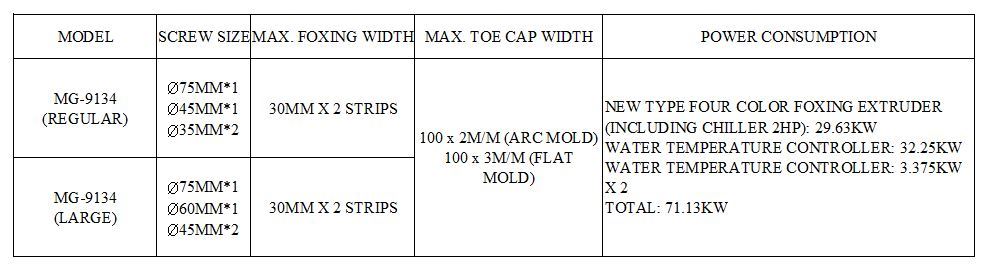

ADVANCED TYPE FOUR COLOR FOXING EXTRUDER

Product Introduction

AUTOMATIC 4 COLOR FOXING PRODUCTION LINE:

1. ADVANCED HELM DESIGN OF THE MOLD HEAD FOR THE CONVENIENCE OF OPENING MOLDS AND CHANGING DIES.

2.IMPROVED TYPE SAFETY FEEDERS FOR ALL MATERIAL-FEEDING ENTRANCES TO STABILIZE FEEDING QUALITY AND TO MAINTAIN OPERATION SAFETY.

3. THERE ARE 2 BRUSHES AND 1 AIR BLOWING SYSTEM ON TOP OF THE ANTI-STICK PASTE TANK FOR REMOVING WATER GLOBS.

4.ADVANCED ELECTRONIC TYPE CONTROLLER AND CLUTCH DEVICE FOR THE CUTTING SYSTEM TO IMPROVE THE UNIFORMNESS OF THE FOXING LENGTH IN ORDER TO REDUCE PRODUCTION LOSS.

5.FOR PRODUCING BEAUTIFUL HIGH QUALITY COLOR FOXING TAYPES, ONE SET OF 30KW WATER TEMPERATURE CONTROLLER IS INSTALLED TO PRECISELY CONTROL 4 EXTRUDER TEMPERATURES. ONE SET OF 3KW WATER TEMPERATURE CONTROLLER TO PRECISELY CONTROL THE EXTRUDING MOLD TEMPERATURE. aND, ONE SET OF 3KW WATER TEMPERATURE CONTROLLER TO PRECISELY CONTROL EMBOSSING ROLLES TEMPERATURE.

6.INSTALL A CHILLER TO IMPROVE FAST-COOLING PERFORMANCE.

7.AFTER MOLD IS INSTALLED, TEMPERATURES AND SPEEDS ARE SET, THE FOXING PRODUCTION IS AUTOMATIC.